A weapon of mass distribution abounding with innovation and patented technology. Alpha was the first to offer an expandable canning platform and the first to use servo technology in the filling and seaming process. Others have followed our lead. We’re flattered. Alpha patented the in-line scale weighing every can prior to seaming. No other quality control, or loss prevention measure compares.

6

2

100

Just over 6 feet long and 1.5 feet wide and 100% mobile, the Beer Cannon makes little impact on precious space and is the premier choice for mobile canners. The Cannon offers expandability from up to 50 cans/min to up to 100 cans/min. No wasted investment, no loss of value, simply grow without growing. Double capacity, same footprint.

Compare the Beverage Cannon to and you’ll see the robust build and careful craftsmanship. You’ll see the best value. The rest are fodder.

Cannon on your front line = Profit on your bottom line

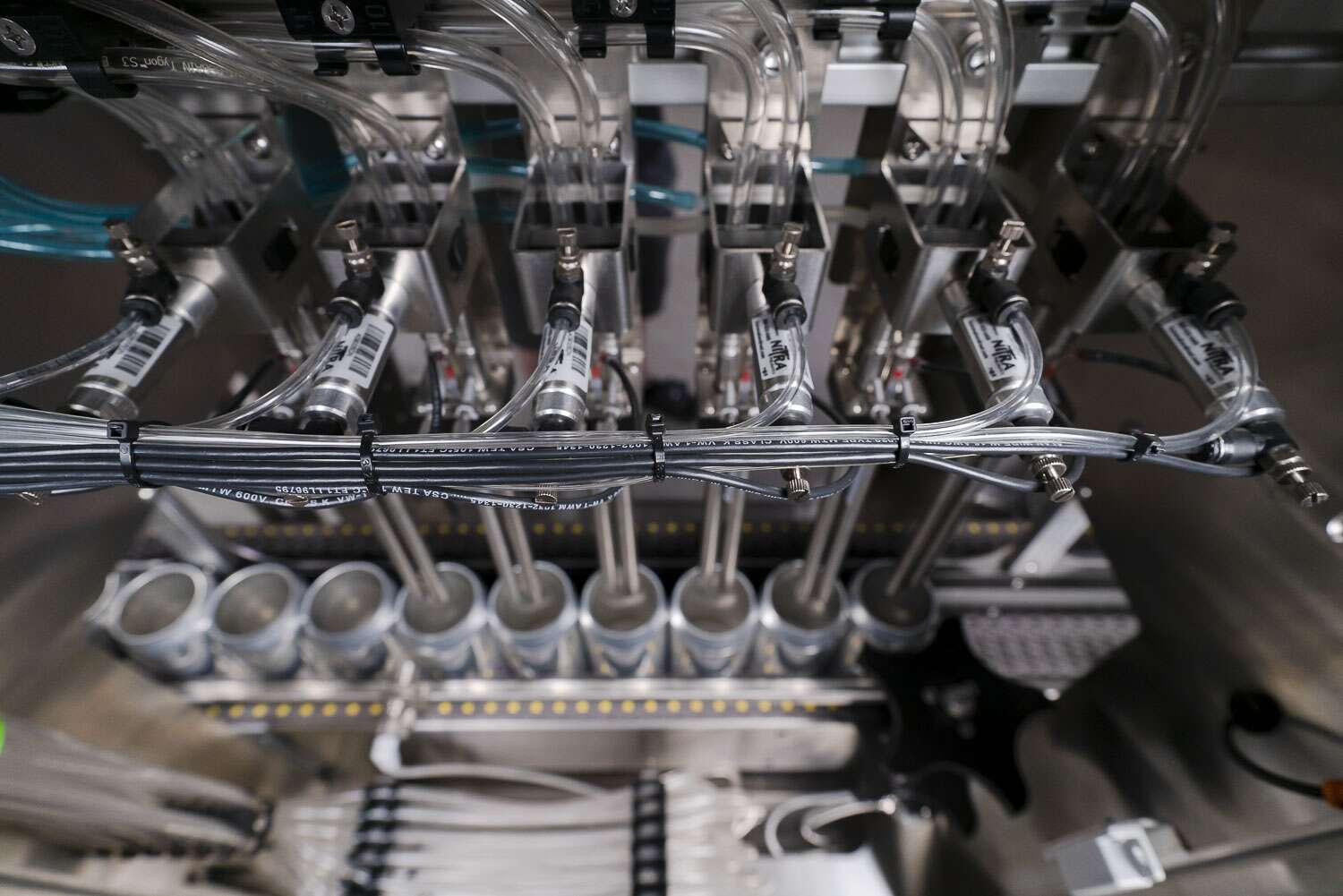

Filler

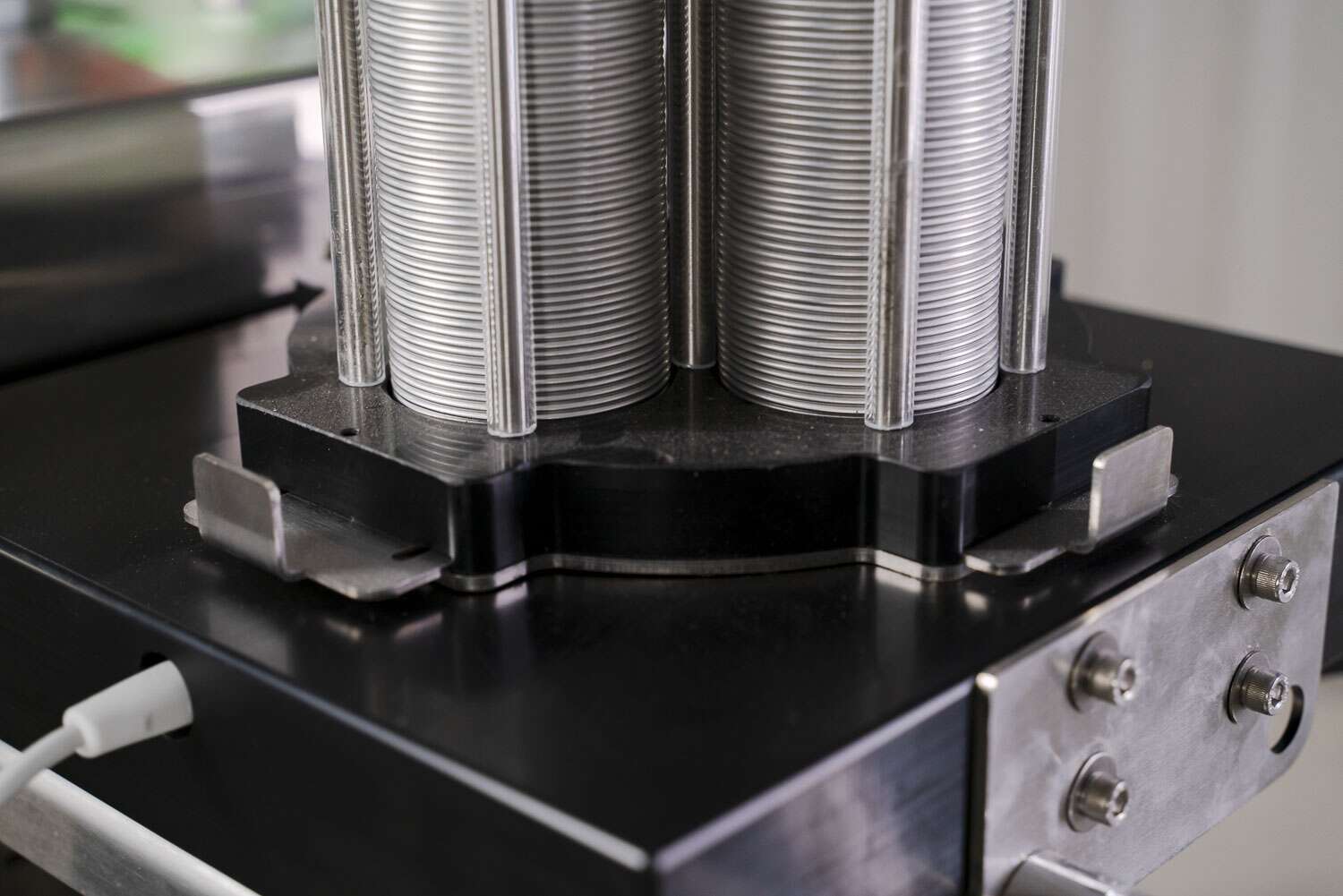

Lid Magazine “The Revolver”

The Revolver, high capacity lid magazine leaves all others wanting. This magazine system holds 4, that’s FOUR full sleeves of lids. Nothing in the industry comes close. It gets better. When the two active chambers empty, simply turn the magazine 90 degrees and open the slide gates to activate the new chambers on-the-fly! Fill your 2nd Revolver (included) at your leisure and with ease. When one magazine is empty, simply lift and replace with the 2nd without stopping. The level sensor alerts when lids are low so you never miss a switch.

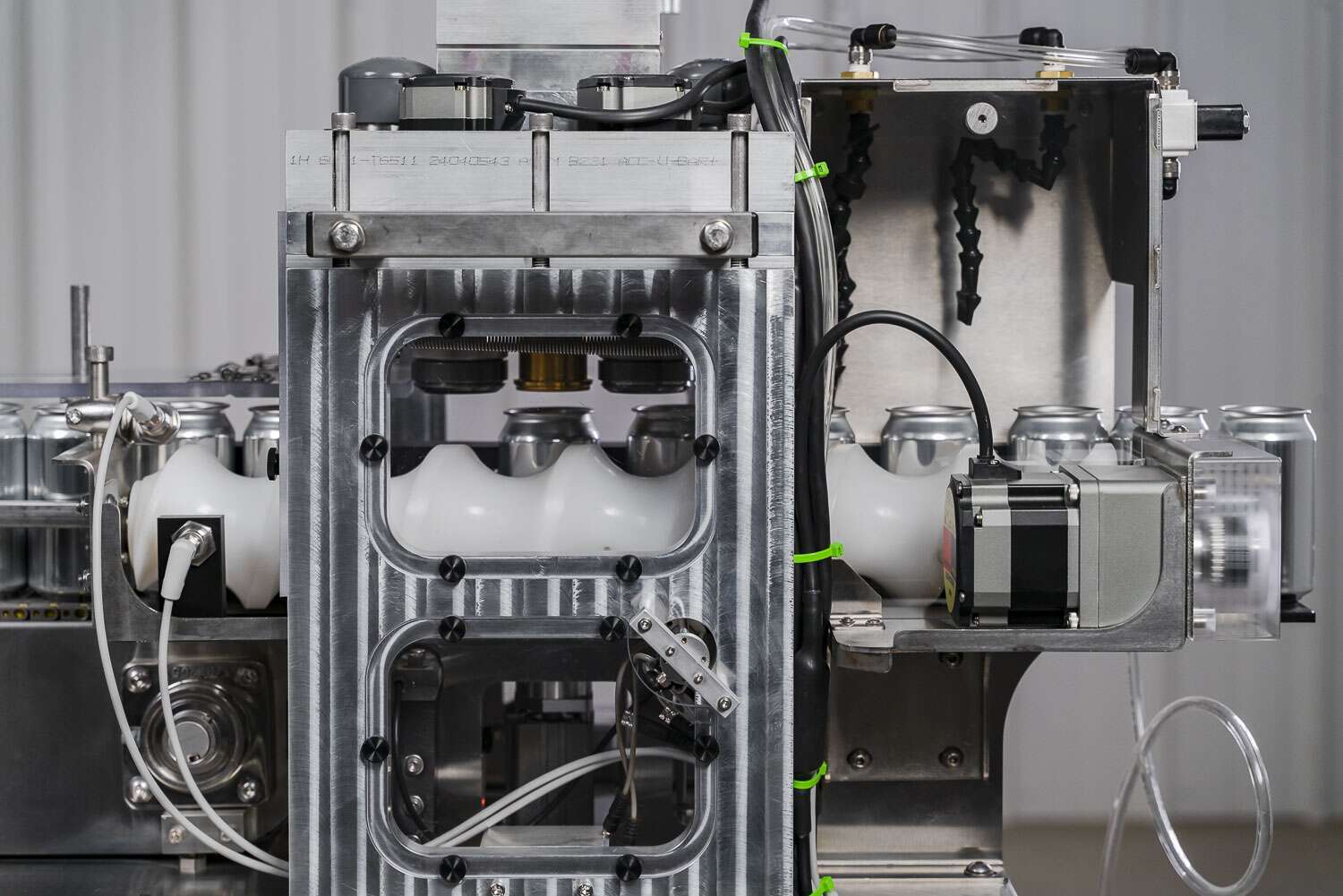

LID APPLICATOR

The dual lane lid applicator provides easy, 4 bolt size change and fine position adjustment on two axis. Alpha’s unique spring tension release and stainless pressure roll-on feature means consistent, reliable lid pick and placement, all day long.

FEED SCREW

Where the conveyor ends, our feed screw takes over. This design moves cans effortlessly over a Delrin (polymer) plate surface through the rest of the operation. Our feed screw is also servo driven and provides fast, quiet, and incredibly smooth can transition to the load cell, the seamer, final can rinse and dry station and onto packaging. No problematic conveyor-to-conveyor “bumper can” transitions. Just perfect, controlled movement, every time.

LOAD CELL CAN WEIGH STATION (Patented)

The patented check weigh station on the Beer Cannon weighs each can prior to seaming. Operator chooses to seam, or not seam any low fills detected.

Low fills are rejected automatically. Load cell also allows prevention of over fill to maximize profit!

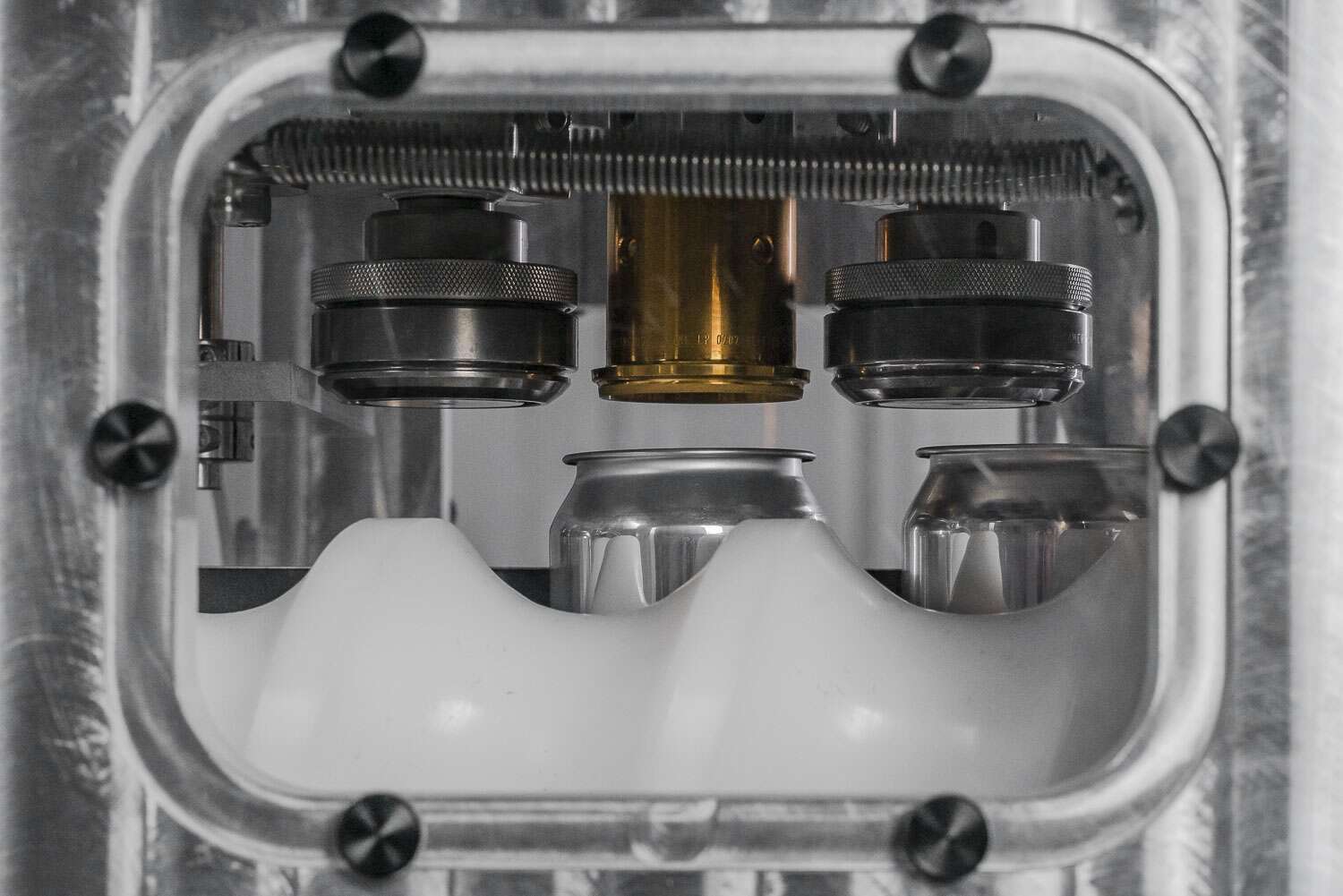

SEAMER

Seam operations 1 and 2 are cam operated and driven by a servo motor. Alpha was the original servo driven seamer. We are flattered by those who have followed. Servo technology offers precise seam adjustments within a thousandth of an inch possible, on-the-fly, right on the touch screen.

Size changes on the seamer are very fast and easy. Simply 4 bolts loosened, and spacers added, or removed, bolts retightened and done. All grease zerks are easily accessed for periodic maintenance. The most critical aspect of any canning operation should hold up for millions of cans.

REJECT STATION | “The Gallows”

Possibly the most fun feature on the Beverage Cannon, sadly is the least used. However, should your patented load cell detect a low fill, or if the missed lid sensor detect a missed lid, what happens next is fun to watch. As your low fill, or lidless can bypasses the seamer, the trap door opens, the can disappears down the chute below and is collected. It’s like something out of “The Goonies.” Put your can back in line and reduce waste. You’ll be sending Pabst cans down “The Gallows” over and over after work. We guarantee it.

RINSE/DRY STATION

Alpha employs burst rinse and dry technology to wash and dry only the cans and not the space between them helping the Beer Cannon to be perhaps the most energy efficient canning line of its kind. The controlled movements that the feed screw offers allows for controlled rinsing and blow-off as well, making the process more efficient and effective.

Alpha offers alternative dryer air supply options to eliminate the bulk of your compressed air consumption.

Want to Know More?

View all canning equipment.

View our entire lineup of canning lines, de-palletizers, labelers, pack tech applicators and date coders.